In

this post we will show a PID temperature control application programmed in

Function Block Diagram. This language is practical to be used in the process

industry, due to the facility in visualizing the process and in manipulating

the instructions of digital, analog signals, alarms, operating mode, among

others.

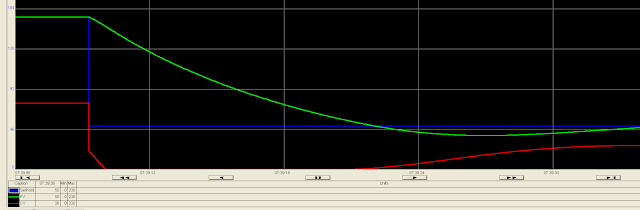

The

PID control will be performed with the PIDE (PID Enhanced) instruction, which

has a PID algorithm proportional to the Error delta. Thus, the regulation of

the CV variable is done with the error variation. The visualization of the

system's response is done with a Trend where the system's SP, PV and CV are

shown.

The

Process Value (PV) is simulated, based on CV, multiplying by a multiplier

coefficient and also by a 5s dead-time and a 10s lag-time, in order to simulate

the response time of a real system.

In

this case, the logic of the analog input signal, the PIDE instruction and the

response simulation were performed in the same routine to facilitate

visualization. However, in a project, it would be better to create AOI (Added

On Instructions) and use the modules created for data exchange. An AOI can be

created, for example, to simulate and test the response of a system.

Step change response:

No comments:

Post a Comment